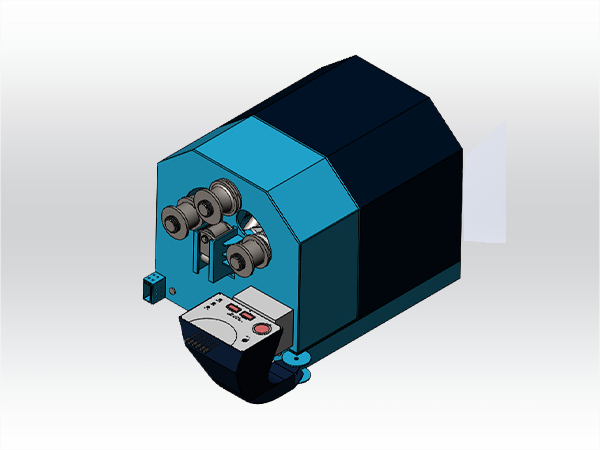

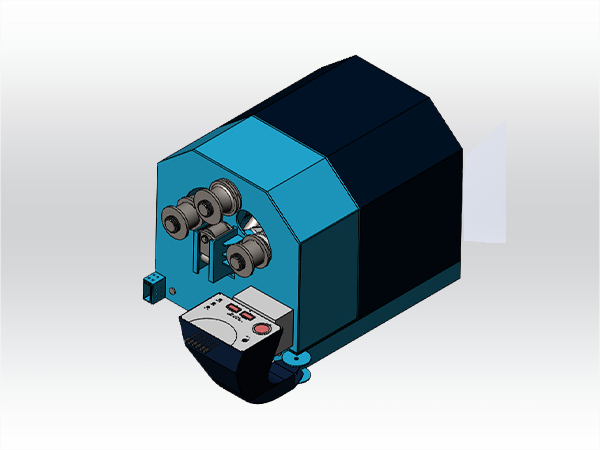

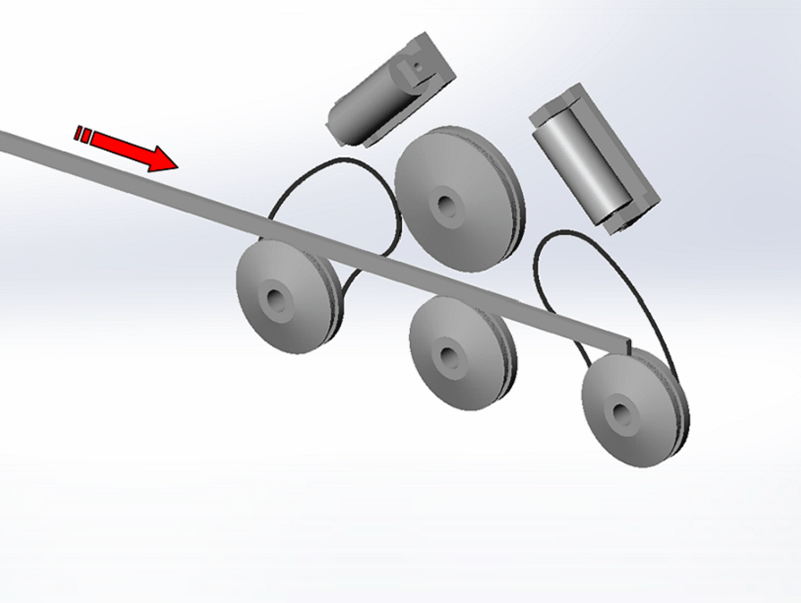

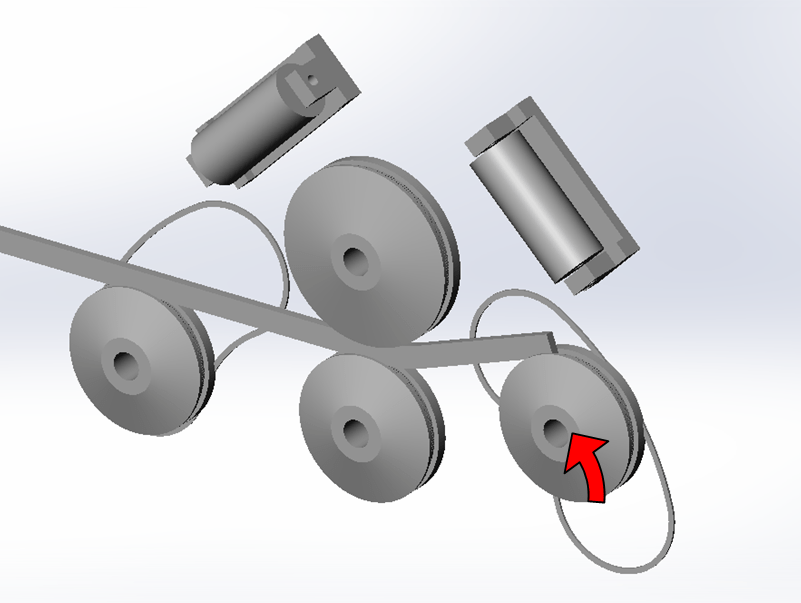

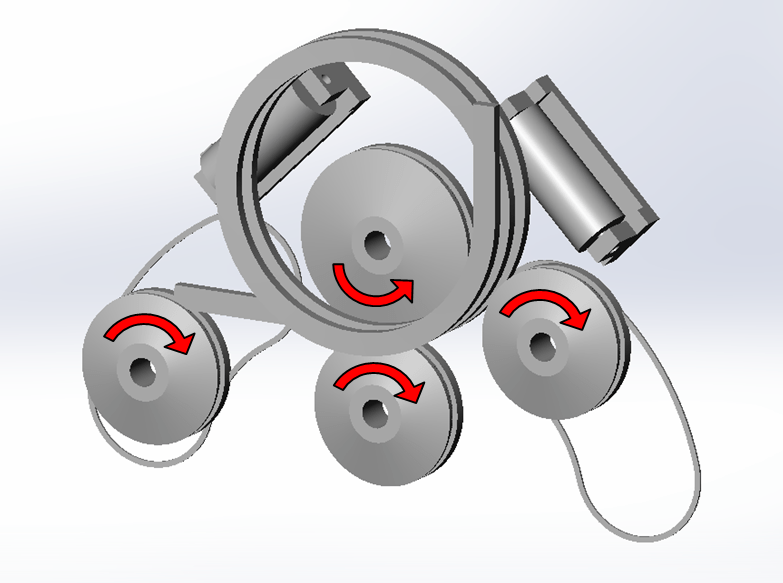

Section placed on a rolling dies

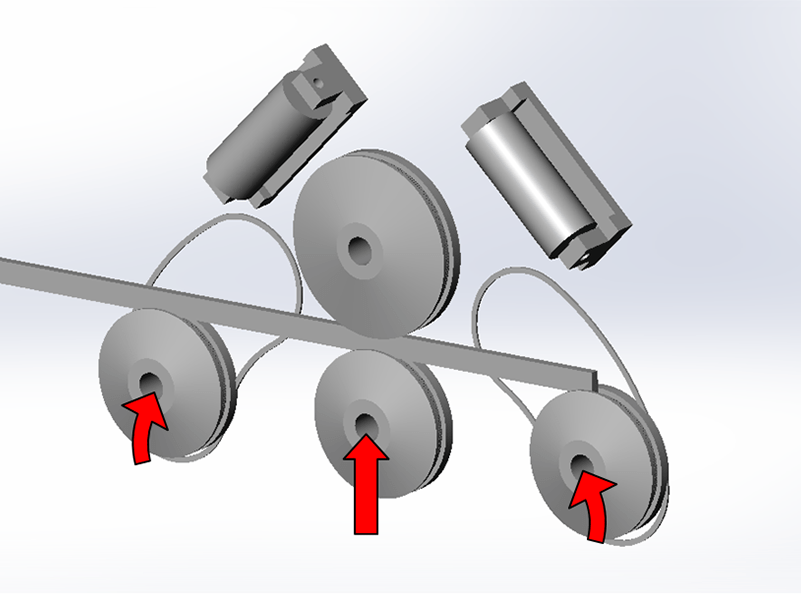

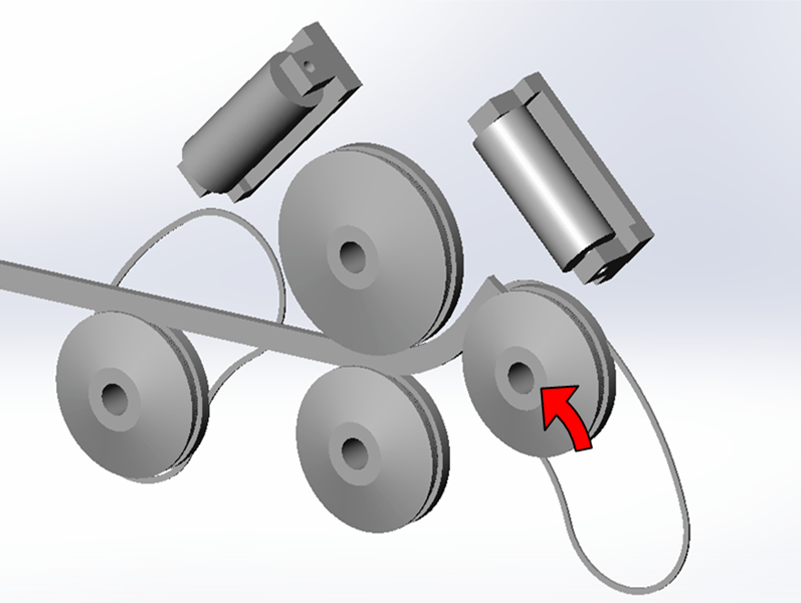

Bottom roll moves up for clamping

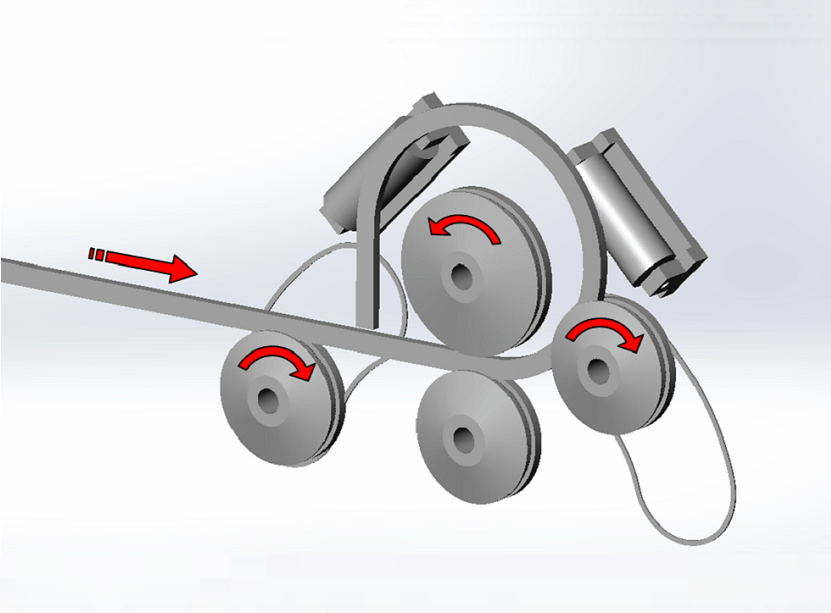

Side roll moves up for pre bending

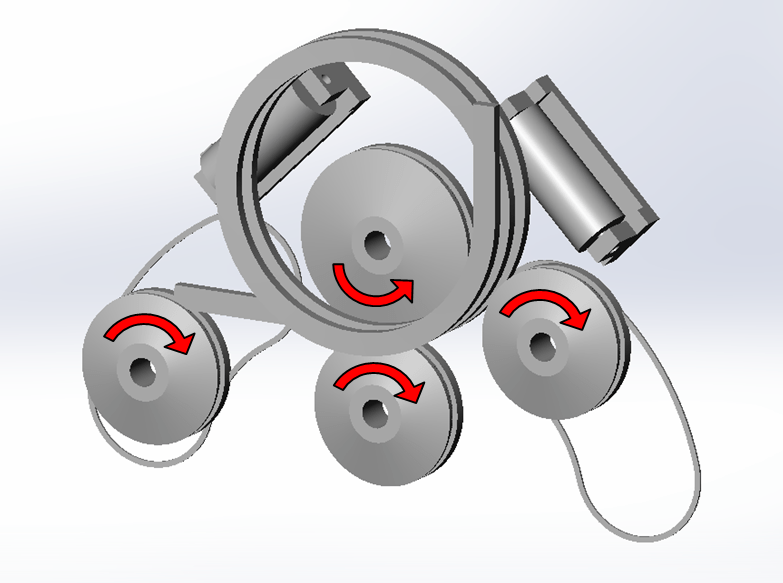

Further position achieved for final dimensions

Pusher used for coiling

Rolling complete

Final Job

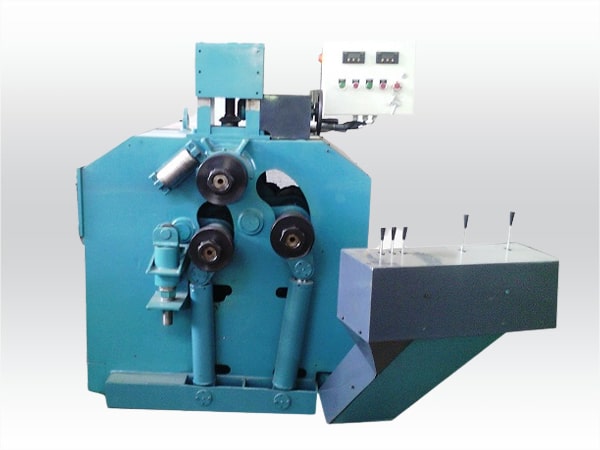

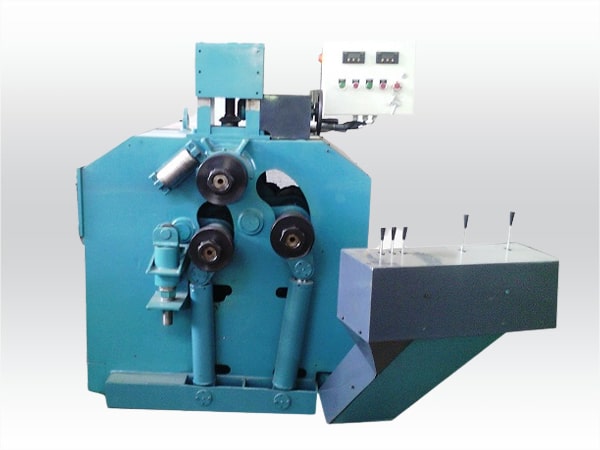

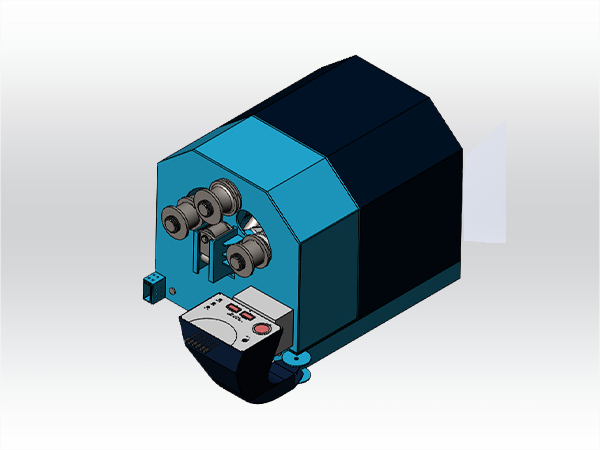

This is low cost machine model available with pre bending facility and most useful for small and medium fabrication workshop.

The machine frame is built from all tested steel plate material. This frame is subjected to stress releaving, sand blasting and epoxy primer painted for corrosion free long lasting machine life. The complete body is machined in cnc machine to achieve built in accuracy.

The side roll up-down movement and roll rotation are fully hydrualic. The side roll up-down position is indicated by digital meter provided on control desk.

In this type of model, all hydrualic actuators movement are through manually operated mobile control walves.

All our machine rolls are mounted in heavy duty roller bearings. Each roller is fitted with two bearing per side (four bearing per roller).

The pusher roller assembly can be given as a option for coil forming application.

An optional feeder table can facilitate loading and machine operation by a single person only.